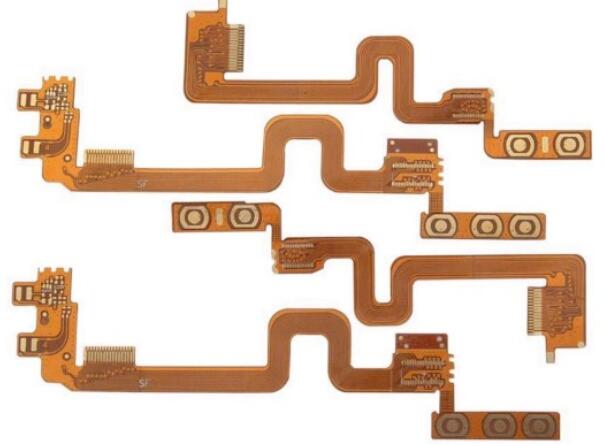

With the gradual development of electronic products towards short, small, light and thin, the advantages of FPC flexible circuit board are becoming more and more obvious, and the market demand is also increasing. At present, the surface processes of FPC flexible board include gold deposition, tin deposition, gold plating, tin plating, OSP, etc. So gold deposition and gold plating are all gold. What is the difference between them? Let's talk about it in detail.

1. What are the aliases of gilding and sinking gold

Gold plating: hard gold, electric gold

Gold sinking: soft gold, chemical gold

2. Origin of alias

Gold plating: through electroplating, the gold particles are attached to the FPC board, which is also called hard gold because of its strong adhesion. The gold finger of the memory module is hard gold, which is wear-resistant. The bound FPC is also generally gold plated.

Gold deposit: Through chemical reaction, the gold particles crystallize and attach to the pad of FPC board. Because of the weak adhesion, it is also called soft gold.

3. Influence of gold plating and deposition on the patch

Gold plating: It is done before the resistance welding. After it is done, it may not clean the green oil and it is not easy to tin.

Sinking gold: After resistance welding, the patch is easy to tin.

4. Process sequence is different

Gold plating: do this process before resistance welding, because gold plating requires two electrodes, one is the FPC board, and the other is the cylinder slot. If the FPC board is finished with resistance welding, it can't conduct electricity and can't be plated with gold.

Gold deposit: after resistance welding, as with tin deposit, the chemical method is to attach gold where there is copper leakage.

5. Influence of gold plating and sinking on electrical appliances

Gold plating: before gold plating, a layer of nickel should be plated first, and then a layer of gold. The metal layer is copper, nickel and gold. Because nickel is magnetic, it has an effect on shielding electromagnetism.

Gold deposit: directly deposit gold on the copper skin. The metal layer is copper gold, without nickel and magnetic shielding.

6. Identification of Gold Plating and Gold Deposition

Gold plating process is magnetic because FPC contains nickel. When identifying gold plating or gold deposition, magnets can be used to attract FPC plates. Attractive is gold plating, and unattractive is gold deposition. In addition, the color is also different. The sunk gold is golden yellow. Because of the large gold surface, the gold plating is generally very thin and tends to be white. Of course, there are also thick gold plating, which is also golden yellow. At this time, it is difficult to distinguish the solder pad.

Online

Service

ConsultationTime:9:00-18:00

Hot

Line

0755-27847787

7*24H Service

Follow

Us

Website

Website