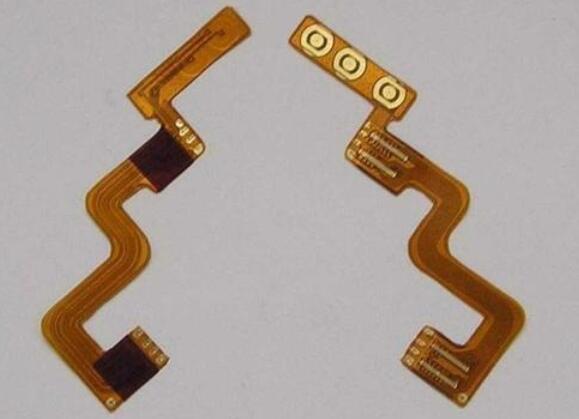

With the continuous development of science and technology and the development of electronic products towards short, small, light and thin, the demand for softboard has been increasing and the application has become more and more extensive. However, there are many partners who are not very clear about what materials are made of softboard. Let's talk about this in detail.

1. Insulating substrate

The insulating substrate is a flexible insulating film. As the insulation carrier of FPC flexible circuit board, the selection of flexible dielectric film requires comprehensive investigation of the heat resistance, covering performance, thickness, mechanical properties and electrical properties of the material. Polyimide film, polyester film and polytetrafluoroethylene film are commonly used now.

2. Adhesive sheet

The function of the bonding sheet is to bond the film and the metal foil, or the film and the covering film. Different types of adhesive sheets can be used for different film substrates. For example, the adhesive sheets for polyester and polyimide are different. The adhesive sheets for polyimide substrates can be divided into epoxy and acrylic. The fluidity and thermal expansion coefficient of the material are mainly investigated when selecting the adhesive sheet.

3. Copper foil

Copper foil is a conductive layer that is covered and bonded on the insulating substrate. After selective etching, the conductive line is formed. Most of these copper foils are calendered copper foils or electrolytic copper foils. The ductility and bending resistance of calendered copper foil are better than electrolytic copper foil. The elongation of calendered copper foil is 20%~45%, and that of electrolytic copper foil is 4%~40%.

4. Overburden

The covering layer is the insulating protective layer covering the surface of FPC flexible circuit board, which plays the role of protecting the surface wire and increasing the strength of the substrate. The protective materials for outer graphics generally include dry film type (covering film) and photosensitive developing type.

5. Reinforcing plate

The reinforcing plate is bonded to the plate at the local position of the flexible plate, which has the super-support and strengthening effect on the flexible film substrate, facilitating the connection, fixation or other functions of the FPC flexible circuit board. Reinforcing plate materials are selected according to different uses, such as polyester, polyimide sheet, epoxy glass fiber cloth, phenolic paper board or steel plate, aluminum plate, etc.

The above is about "what materials are made of fpc soft board", which is organized by Xiao Bian. I hope it can help you. If there is any unclear place, please contact our customer service to answer for you.

Online

Service

ConsultationTime:9:00-18:00

Hot

Line

0755-27847787

7*24H Service

Follow

Us

Website

Website