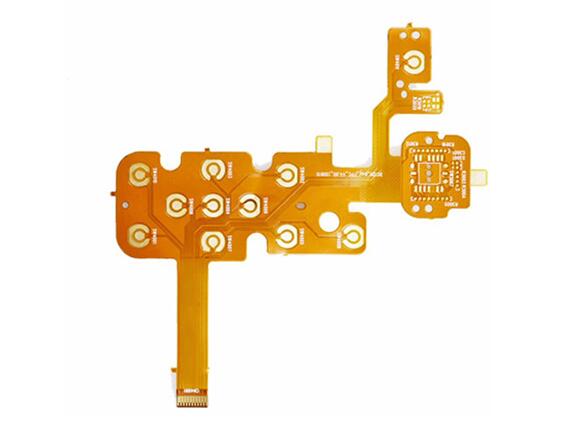

The FPC soft board can only work for electronic products after SMT placement. Each part of the FPC circuit board is very important, so the details of each step are very important in production. What parts are the FPC board composed of? Let's talk about it in detail.

1. Dielectric layer

It is used to maintain the insulation between lines and layers, commonly known as substrate.

2. Silk screen

This is an unnecessary component. Its main function is to mark the name and position box of each part on the circuit board for convenient maintenance and identification after assembly.

3. Line and drawing

The circuit is used as a tool for conducting between the components. In design, a large copper surface will be additionally designed as the grounding and power layer. Lines and drawings are made at the same time.

4. Surface treatment

The main factor that directly determines the quality and positioning of an FPC flexible circuit board is the surface treatment process. At present, the common surface treatment processes include gold, silver, gold, tin, OSP, etc.

5. Cover film

FPC covering film can also be called protective film, which is mainly used to protect the copper foil from exposure to the air and avoid oxidation of the copper foil; It covers the subsequent surface treatment and plays the role of resistance welding in SMT.

6. Hole

The through hole can make more than two layers of lines connected to each other.

Online

Service

ConsultationTime:9:00-18:00

Hot

Line

0755-27847787

7*24H Service

Follow

Us

Website

Website