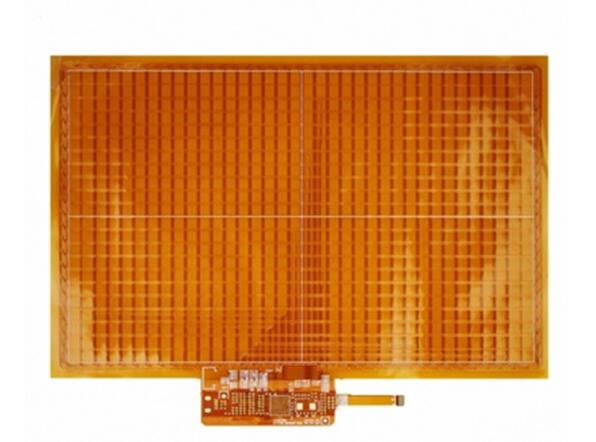

For FPC soft board products, CVL covering film is a very important raw material, and its performance plays a vital role in product quality. However, during the pressing process, the CVL adhesive is in a semi-cured state and has certain fluidity.

When the fluidity of CVL glue is relatively large, it is easy to cover the welding pad, reduce the effective area, and cause glue stains, affecting the welding; On the contrary, when the fluidity of CVL glue is relatively small, it is easy to cause bubbles in the product. So, how to improve the problem of lamination and glue overflow of FPC soft board covering film? Let's talk about it in detail according to the situation of the factory.

1. Improve from "people"

When using the fake pasting machine to fake press, each product must be separated from the glass fiber cloth to prevent the CVL pressure deviation, resulting in glue overflow; The use of TPX release film can effectively control the occurrence of overflow for products with high requirements for overflow; When pressing the plate, the CVL faces up or down, and the influence on the overflow is also different. In addition, the lamination structure of different presses is different, and the influence on the CVL orientation is also different. The CVL orientation needs to be selected according to the actual situation.

2. Improve from the "machine" aspect

The unevenness of the press table will cause excessive local pressure of the product, which will lead to abnormal glue overflow. The 12-point method can be used to test the flatness of the press table regularly with pressure-sensitive paper. For pressing soft plates with different thickness, such as double-sided plate/multi-layer plate, different laminated structural materials will be selected for reasonable matching, so as to ensure that the product can be compacted without glue overflow. Green silica gel pad, glass fiber cloth and other materials with good plastic absorption performance can be selected for matching, which can effectively improve the bad glue overflow.

3. Improve from the "material" aspect

The bad overflow of CVL is often related to the incoming materials. For the CVL provided by the supplier, the overflow quantity of each batch shall be tested and monitored strictly according to the control scope. If the incoming material of TPX release film is abnormal, it will lose the glue blocking function and lead to the occurrence of bad glue overflow, so it is necessary to conduct regular sampling inspection on the incoming material of TPX. The combination of FCCL and CVL is inappropriate. For example, if the thick AD glue CVL is matched with the thin copper thick product, it is easy to cause excessive glue overflow.

4. Improve from the aspect of "law"

By reducing the molding time and pressure of the rapid press, lowering the temperature and extending the pre-pressing time, the bad glue overflow can be obviously improved.

5. Improve from the "ring" aspect

The storage shall be carried out in strict accordance with the conditions of CVL storage warehouse, and the storage humidity, temperature and time shall be controlled. At the same time, the process of CVL from the opening/drilling/punching process is not easy to be too long. The production time of auxiliary materials should be well controlled to prevent CVL from moisture absorption during storage and production. If the CVL is affected by moisture due to improper storage, it can be pre-baked at 60 ℃ for 2 hours at low temperature to reduce the overflow. In addition, the CVL to be fitted also needs to pay attention to the storage conditions.

Online

Service

ConsultationTime:9:00-18:00

Hot

Line

0755-27847787

7*24H Service

Follow

Us

Website

Website